Description

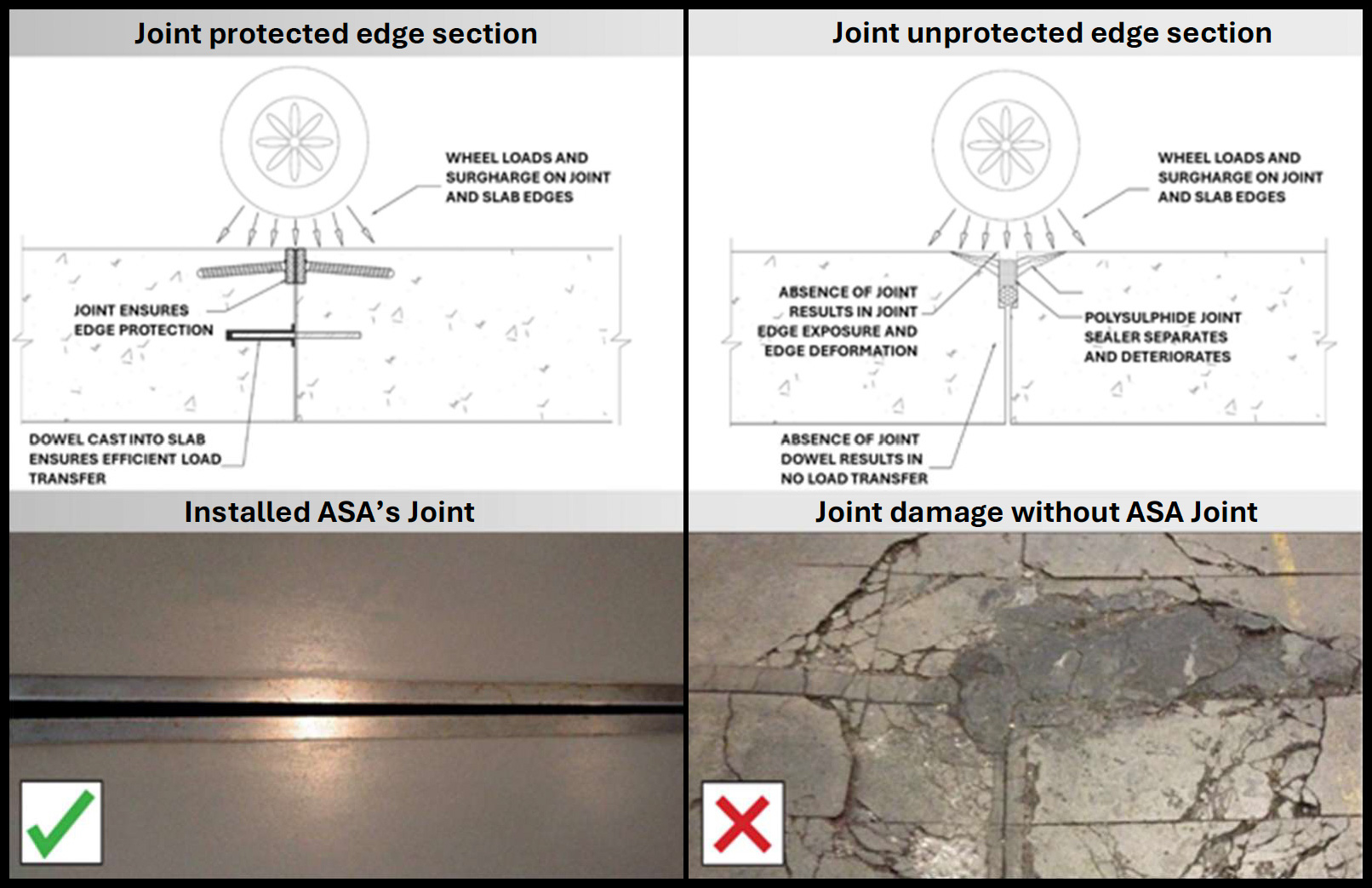

Why You Need an Armour Joint

Concrete floors are constantly exposed to heavy loads, hard-wheeled traffic, and shrinkage or thermal movement. Without proper joint protection and load transfer, slabs quickly suffer cracking, spalling, and costly downtime.

An Armour Joint solves these challenges by:

- Protecting slab edges (arrises): The steel armour prevents the brittle concrete edge from chipping or breaking under forklift or racking loads. This extends the life of the floor and keeps it safe for operators.

-

Ensuring reliable load transfer: Integrated plate dowels distribute loads evenly across adjoining slabs, reducing stress concentration and preventing joint step-faults. This maintains a smooth transition between bays, even under extreme loading.

-

Allowing free slab movement: Unlike traditional round bars that lock slabs, the plate dowel system permits two-way horizontal movement while stopping vertical displacement. This accommodates shrinkage and temperature changes without cracking.

-

Reducing maintenance costs: By keeping joints intact and preventing early deterioration, an Armour Joint significantly cuts long-term repair and downtime expenses.

-

Achieving high-performance floors: Prefabricated, straight joint assemblies enable contractors to cast super-flat and high flatness category floors demanded in modern warehouses, logistics hubs, and industrial facilities.

Joint Armouring and Load Transfer for Construction Joints

Joint Armoured construction joint with 10mm wide steel Joint Edge Protection and Dowel Load Transfer System.

Key Benefits

- Heavy-duty arris protection: Cold-drawn steel edge strips protect joint arrises from impact/spalling.

- Superior load transfer: Plate Dowel offers high bending & shear capacity and better “burst-out” performance than continuous/round bars; allows lateral (in-plane) movement, stops vertical steps.

- Flatness friendly: Continuous, straight formwork helps achieve tight flatness (super-flat) floor categories.

- Complete system: Factory intersection units (4-way, T, L, dock-leveller corners) protect the most vulnerable nodes.

Typical Applications

Warehouses, logistics hubs, high-bay distribution, factories, depots, dock-leveller thresholds, and other heavily trafficked industrial floors (ground-bearing or suspended).

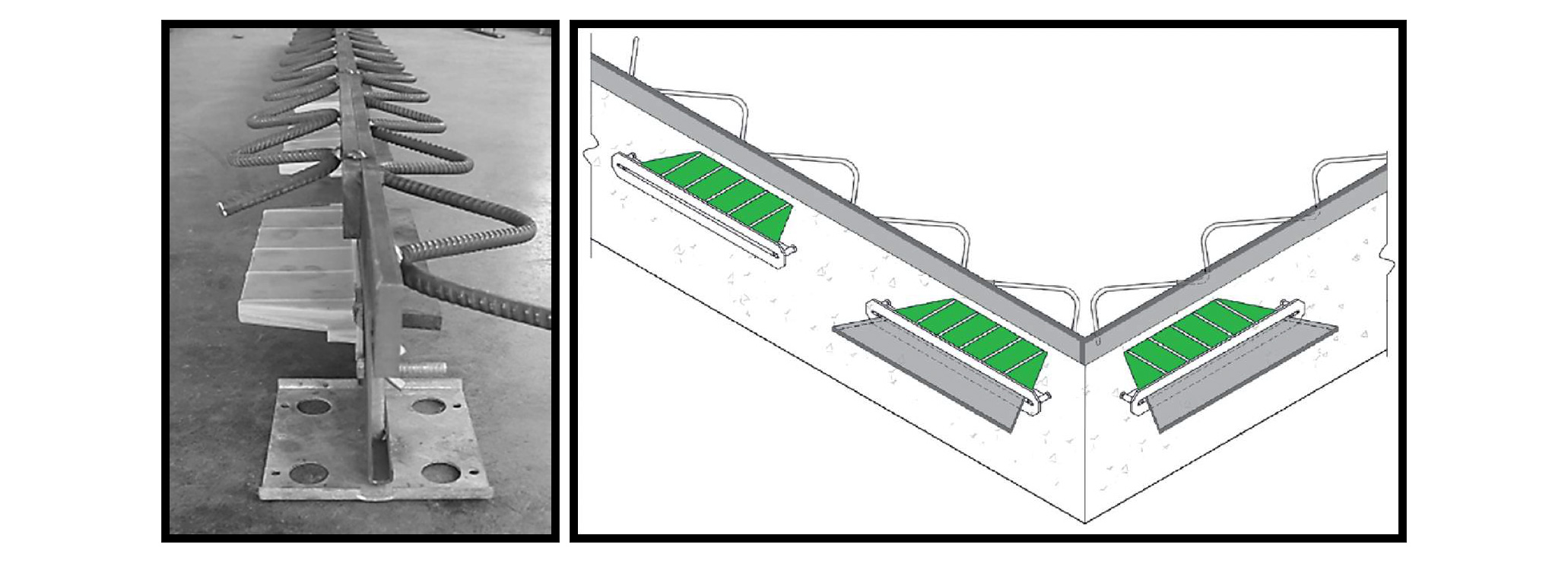

System Components

| Armour Joint (edge assembly) | Dowel (plate dowel with sleeve / pocket former) |

|---|---|

|

|

Design note: Plate dowels + sleeves are preferred over keyed joints for reliable load transfer; ACI 302.1R recommends doweled joints in hard-wheeled traffic and cautions against keyed joints where load transfer is required

Performance (Plate Dowel)

Ultimate capacities (single 10 mm trapezoidal plate)

- Bending: 318.2 kN

- Shear: 151.93 kN

- Bearing: 123.4 kN

Use for relative comparison; final design per Engineer design.

Why plate vs round?

Plate dowels present a wider effective bearing area, reduce restraint, and allow lateral movement while maintaining alignment/LTE. Round bars allow shrinkage in only one direction and can lock slabs if misaligned.

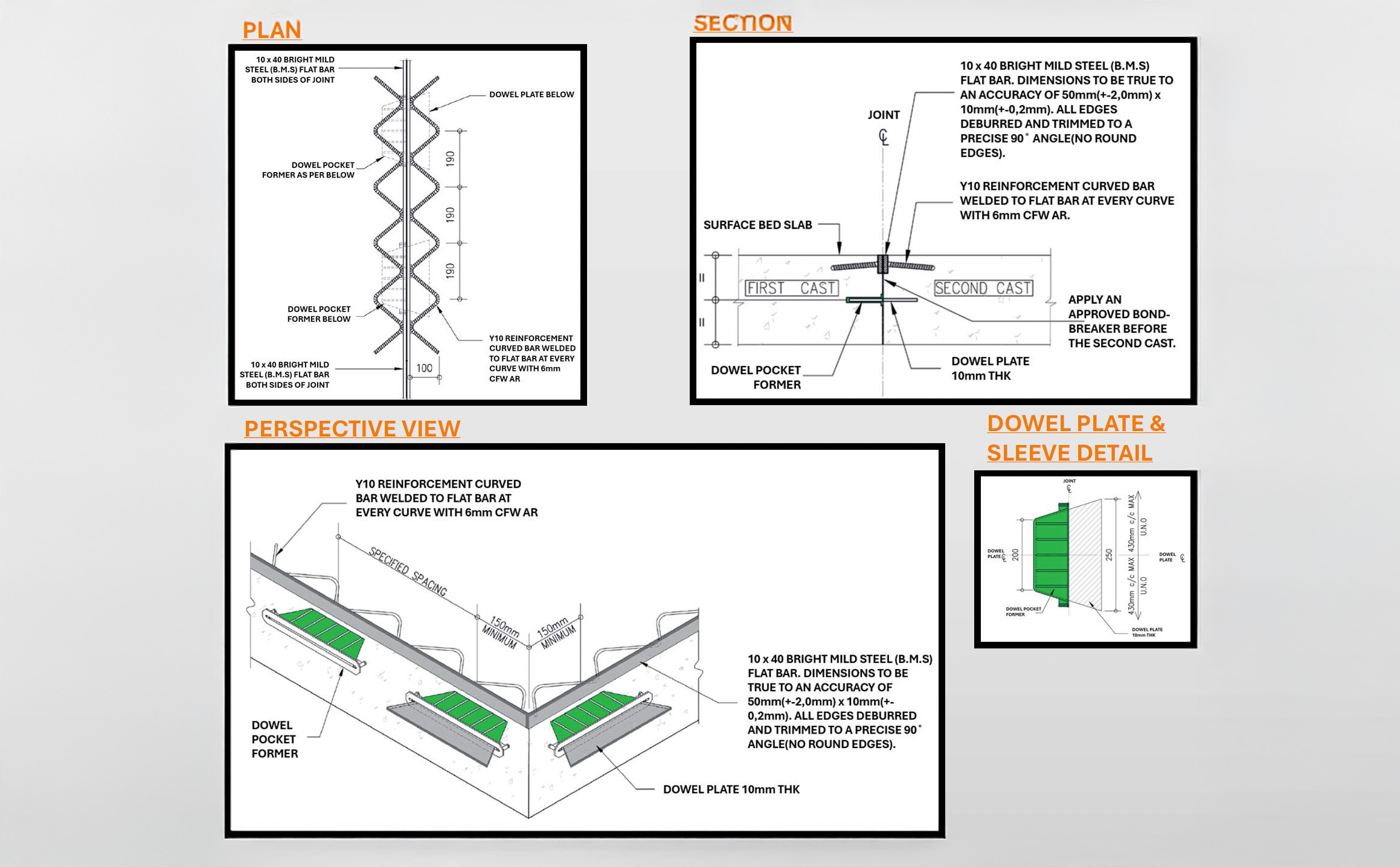

Dimensions & Materials (Typical)

- Section length: 3,000 mm per straight run; lapped joints.

- Heights: Sized to slab thickness (engineer to specify).

- Arris strips: Cold-drawn steel, 10 mm × 40 mm nominal.

- Sleeves: HDPP (high-density polypropylene) pocket formers.

- Finish options: Black or Galvanized

Design Guidance & References

- TR34 (4th ed.) is the prevailing guideline for industrial floors; dowel capacities and joint design follow TR34 Sec. 6.5 failure modes (shear, bending, bearing) and punching checks.

- ACI 302.1R: Use dowels where heavy/hard-wheel traffic or reliable load transfer is required; keyed joints are not recommended for load-transfer-critical areas

Engineer of Record must verify slab thickness/reinforcement, joint opening, dowel size/spacing, LTE targets and punching at the joint for each project per TR34/ACI and loading.

Joint Intersection Unit

The most vulnerable area of the floors slab is the corner or joint intersection. ASA’s Joint is the only system that provides precision prefabricated joint intersection units to ensure that this vulnerable area is as well protected as the remainder of the joint.

- Precision prefabricated corner and joint intersection units.

- Connects to lapped lengths of the Armour Joint.

- Sections Available: 4-way joint intersections, 3-way T jointintersections, 90° Corners and Dock Leveller corner units.

Joint Selection Criteria

Joint D6 (Supplied with Diamond Dowels) to be fixed at 375mm centres. For ground bearing slabs up to 240mm thick, 10mm maximum joint opening and sawn induced joints at approx 4m ctrs.

Joint V1O-600 (Supplied with Dowels) to be fixed at 600 mm centres. For suspended floor slabs, joint less, steel fibre or bar reinforced up to 240mm thick and 20mm maximum joint opening

V1O-430 (Supplied with Armour Joint Dowels) to be fixed at 430mm centres. For slabs above 240mm thick.

In short: Armour Joints protect your investment by creating a durable, low-maintenance joint system that delivers smoother operations, safer working conditions, and longer-lasting floors