Description

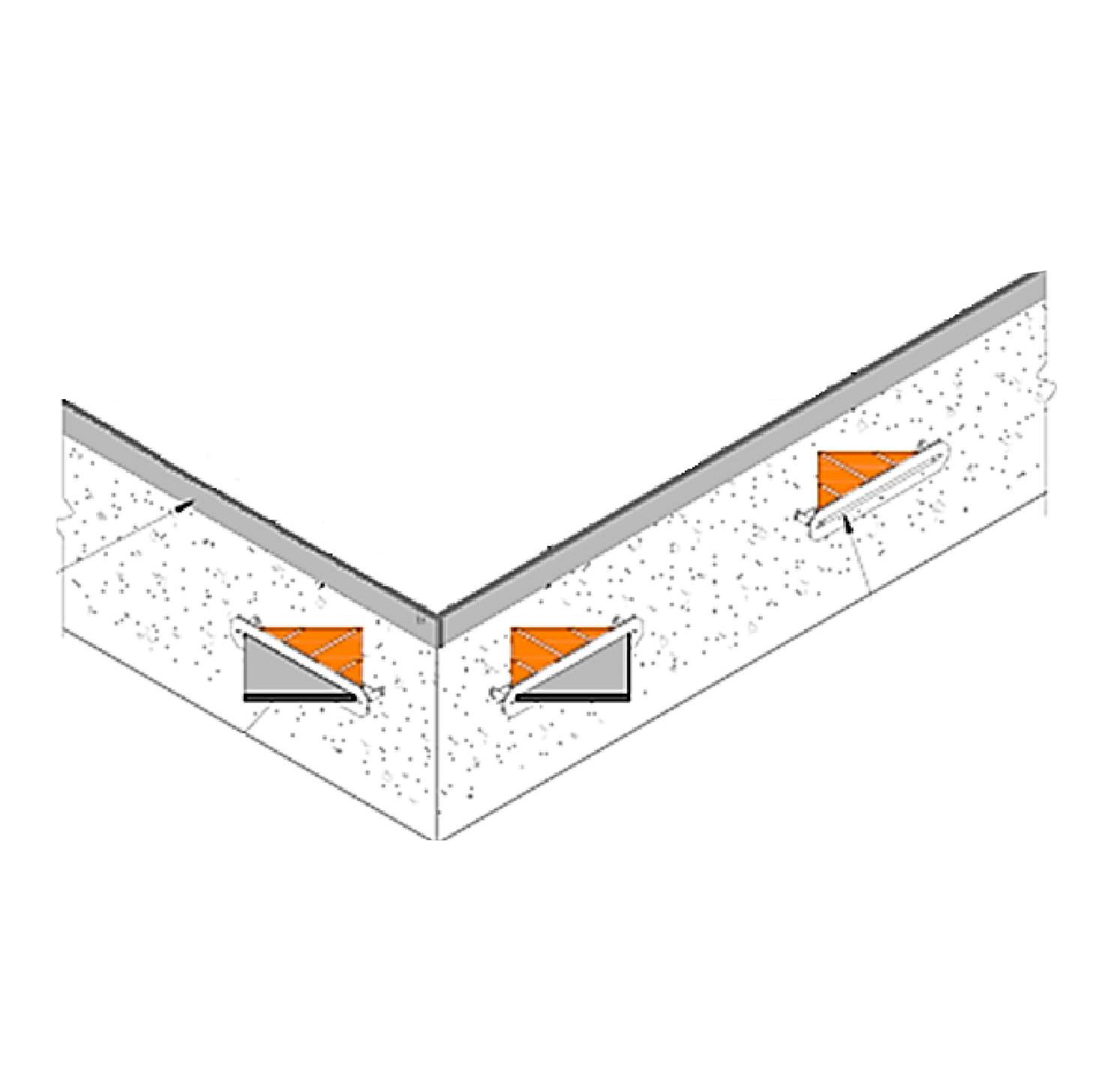

Installation Snapshot

Fix Diamond Dowel sleeves to the first-side formwork at the engineer’s specified spacing and elevation.

- Place and finish concrete on the first side; cure as required.

- Strip formwork; insert Diamond Dowel plates fully into the sleeves.

- Place and finish the second-side pour, ensuring the joint is straight and sleeves remain aligned.

- Cut contraction joints as specified; protect arises (consider armoured joints in high-traffic zones).

Technical Options

| Key Advantage | What it Means |

|---|---|

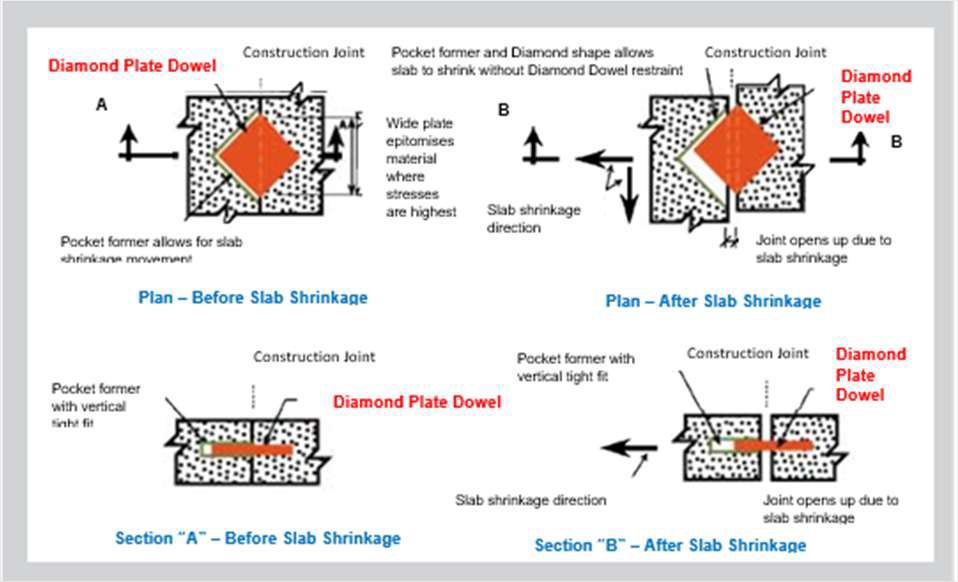

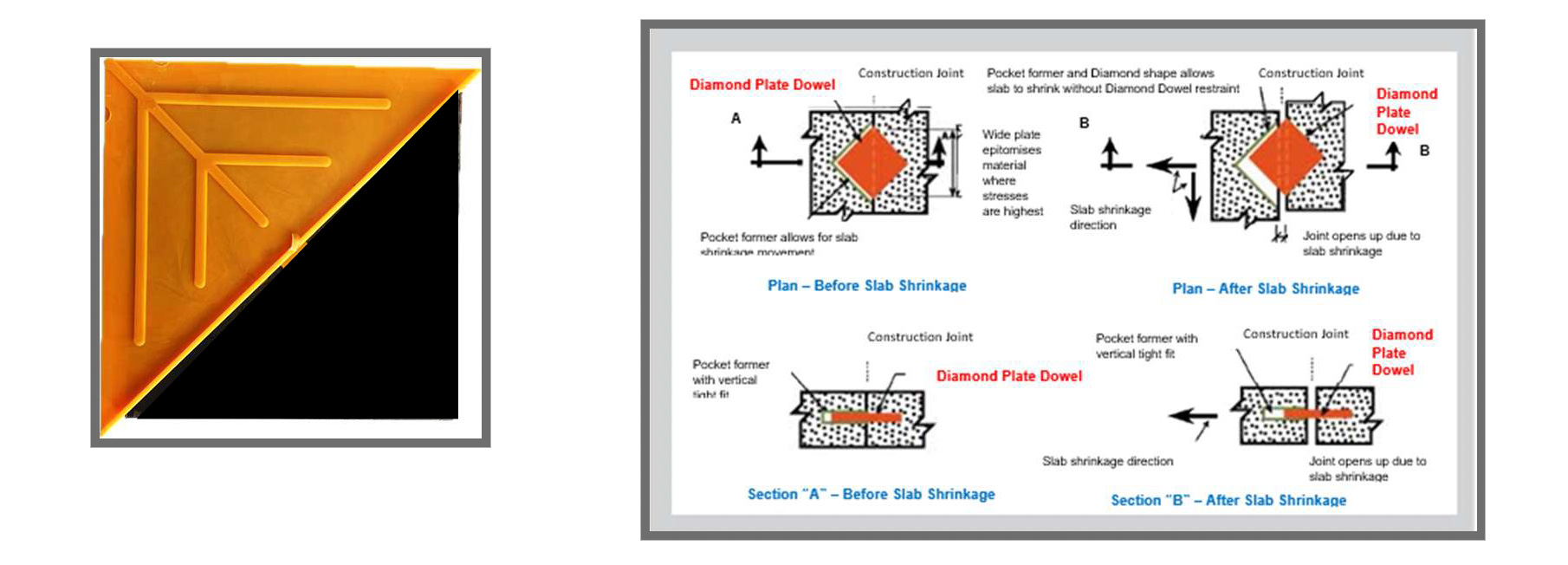

| Unrestricted joint movement | Prevents restraint-induced cracking while maintaining slab alignment. |

| Superior load transfer | Optimizes floor life under heavy wheel and point loads. |

| Fast installation | No drilling in formwork; sleeves fix to forms for rapid setup. |

| Plate thickness | 6 mm |

|---|---|

| Typical plate material | Structural steel plate |

| Sleeve type | High-strength polymer, nail-on flange for formwork |

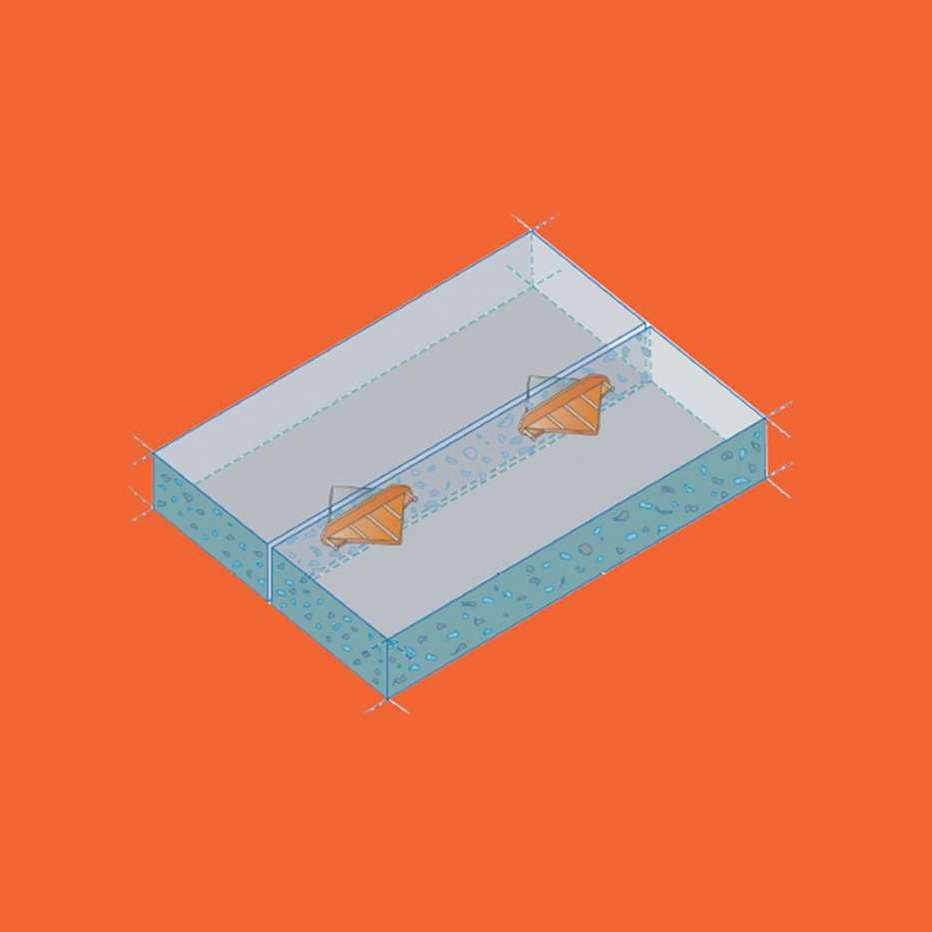

| Joint movement | Two-way horizontal movement; no vertical differential |

| Typical use | Slabs-on-ground, hardstands, high-bay warehouses, logistics hubs |

| Finish compatibility | Compatible with armoured joints; suitable under hard-wheeled traffic |