The Ultimate Guide to Essential Hand Tools for Concrete Finishing Professionals

Introduction

When it comes to concrete finishing, the tools you choose are just as important as the skill you bring to the job. Whether you’re working on a residential driveway or an industrial warehouse floor, having the right-hand tools is the key to achieving a smooth, level, and durable finish. Investing in top-quality tools doesn’t just improve your efficiency—it enhances your craftsmanship, reduces errors, and extends the lifespan of your work.

1. Trowels: The Backbone of Concrete Finishing

BETONELLI hand tools are excellent for concrete surface preparation, cutting, and shaping.

A concrete finisher’s job is incomplete without a reliable trowel. It’s the primary tool for smoothing and shaping wet concrete, and using the right one ensures durability and precision.

– Betonelli Steel Finishing Trowels. Ideal for polished, even finishes. High-quality stainless-steel trowels resist rust and last longer.

– Betonelli Magnesium Floats: Lightweight tools essential for opening the surface, pushing down aggregate, and minimizing user fatigue.

2. Screeds: Achieving a Perfectly Level Surface

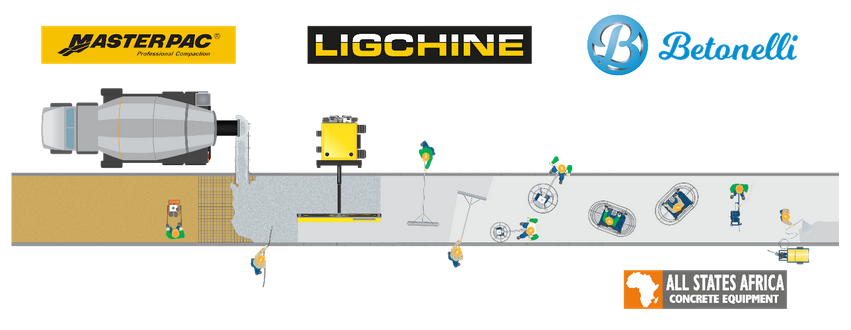

– LIGCHINE Laser Screeds: LIGCHINE laser-guided screeds from All States Africa Concrete Equipment deliver outstanding level accuracy on large slabs.

– GEO-FENNEL laser levels are ideal for screed alignment and accurate slab grading.

Screeding is the foundation of a flawless finish. Without a proper screed, achieving a level surface is nearly impossible.

– Betonelli Aluminum Screeds: Lightweight yet sturdy for removing excess concrete.

– Betonelli Vibrating Screeds: Perfect for larger jobs, these tools both level and compact concrete.

3. Betonelli Edgers & Groovers: The Finishing Touches

Sharp edges and clean lines separate amateur work from professional craftsmanship.

– Betonelli Concrete Edgers: Create smooth, rounded edges that resist chipping.

– Betonelli Groovers: Produce control joints to prevent cracks during curing.

4. Betonelli Bull Floats: Smoothing Large Surfaces

– Betonelli provide robust, high-performance bull floats for professional finishing results.

Bull floats are essential for large-scale projects, helping smooth and level surfaces before the concrete sets.

– Betonelli Magnesium Bull Floats Lightweight, rust-resistant, and easy to handle.

– Betonelli Adjustable Handles: Increase reach without sacrificing control.

5. Betonelli Concrete Brushes: Enhancing Traction & Aesthetics

Betonelli Float Broom and Flat Wire Broom, adding texture is crucial for both functionality and aesthetics.

– Betonelli Soft-Bristle Brushes: Best for decorative finishes.

– Betonelli Flat Wire Broom: Used for slip-resistant finishes on driveways and sidewalks.

6. Chisels & Hammers: Precision Adjustments

– BOSCH and EJOT power tools offer unmatched efficiency for breaking, chipping, and refining concrete sections.

Corrections are a part of every concrete job.

– Bricklayer’s Hammer: Useful for minor corrections and breaking small sections.

– Cold Chisels: Provide accurate detailing and removal of hardened material.

7. Betonelli Knee Boards: Comfort & Control

Knee boards are necessary for up-close work on fresh concrete.

– Betonelli Lightweight Knee Boards: Made to prevent marks and ensure user comfort.

8. Measuring & Marking Tools: Precision Matters

– GEO-FENNEL digital levels, laser distance meters, and line lasers elevate layout precision and workflow accuracy.

Accuracy before the pour prevents costly mistakes.

– Heavy-Duty Tape Measures: For accurate project dimensions.

– Chalk Lines: Ideal for marking layout lines and joints.

Why Quality Tools MatterAt All States Africa Concrete Equipment, choosing the right tools isn’t just about ease, it’s about performance, durability, and savings.

- Durability: Tools that last through demanding conditions.

- Efficiency: Complete tasks faster and more accurately.

- Precision: Achieve flawless professional results.

- Cost Savings: Minimize rework, labor, and material waste.